THE LEADING PVC EDGING MANUFACTURER

Located in the North-West part of Malaysia in the state of Perak, Perceptive Profile has its own manufacturing facilities and undertakes full R&D and production on site. Perceptive Profile is the leading player in PVC Edging products.

Over 26 years of experience

1995

PPSB incorporated with main production is PVC Edging, such as PVC Furniture Profiles and Edgings (Furniture Stripe) for the furniture industry.

Started with only four production lines and initial production capacity of 100,000 linear meters of PVC profiles per month.

2004

Rapidly grew to 17 single screw PVC extrusion lines and 1 twin screw Bausano PVC profile extrusion line in the extrusion department.

Printing department is equipped with five lines of three color automatic printing machines with UV coating and another line of f our head automatic hot stamping machines

2005

Perceptive moved towards a new platform dimension through Research and Development (R&D) and after investing a significant sum in upgrading the bio technology technique, finally succeeding in developing a Hi Tech environment protection material for the future Wood Plastic Composite(WPC). Full production has been carried out.

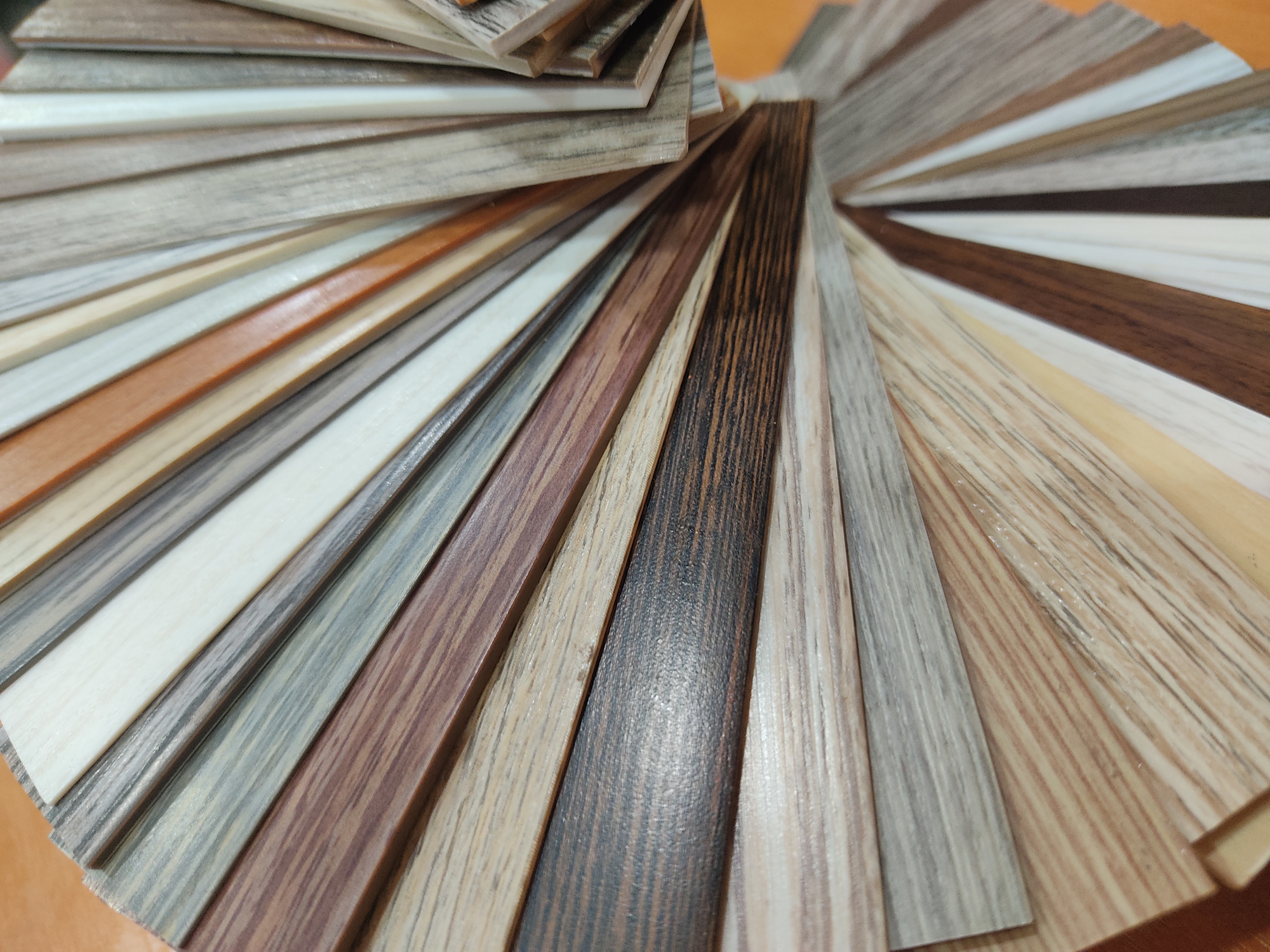

PVC (PVC Edging)

PVC, one of the most common materials that can be used in production of the PVC industry for various industries. PPSB is conducting it’s production of all PVC Edging in compliance with American and European standard that ensuring safety, free from lead and cadmium as well as hazardous substances.

WOOD PLASTIC COMPOSITE (ABWOOD®)

The materials used by PPSB have an important role in preserving our environment. We can fully optimize and re-use virtually all sorts of natural waste such as wood flour, saw dust & etc to create an environmentally friendly and 100% recycled as well as product which is Agro-Bio Wood and carries the trade name of ABWOOD®.

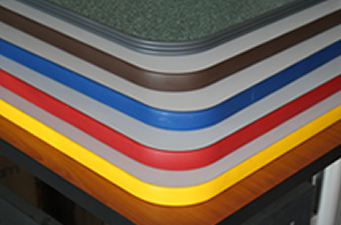

PVC T-Mould

Go 'Green' With Us

Sustainable landscape architecture, a designed green lung in the city and neighbourhood primarily aims to elevate the living standard and social prosperity of the community. We are in support of this noble initiative long ago. We are also the green expert partner in this area.

C.Y. Cheah

Managing Director

ABWOOD® Product Applications

Deck Board

ABWOOD decking is made by combining Saw Dust fibres with plastic(PE,PP or PVC, depending on the customer’s requirements) to create a durable decking material.

Outdoor Furniture

ABWOOD® out door furniture can be supplied and installed in all type of conditions and locations from schools, homes, parks etc. ABWOOD® outdoor furniture

Railing & Fences

ABWOOD® profiles are most suitable and the perfect replacement for wood or other materials when it comes to building outdoor railings.

Doors

ABWOOD doors are unique and distinctive with the benefits of Anti-Termites and Water Resistance.

Profiles

Variety Design of ABWood Profile that introduce to suit numerous application as well as others related fields.

Metal Reinforced

In the search o a new material to enchance our production, we now present a new range o metal reinforced WPC products for building structures.

ABWOOD® Decking more environmentally friendly

ABWOOD® is a leader in manufacturing composite decking and sustainability is at the core of our practices. Our composite product is made of Saw dust fibres (around 65-70%) and plastic-PE,PP (around 30-35%). We then add a blend of additives, which help the product to resist fade, and a pigment to give each finished board it’s distinctive colour.